Installing equipment beginning with screen printer.

Surface Mount Technology Department

Pick & Place and Reflow installed.

Describing process to the Prime Minister of New Zealand.

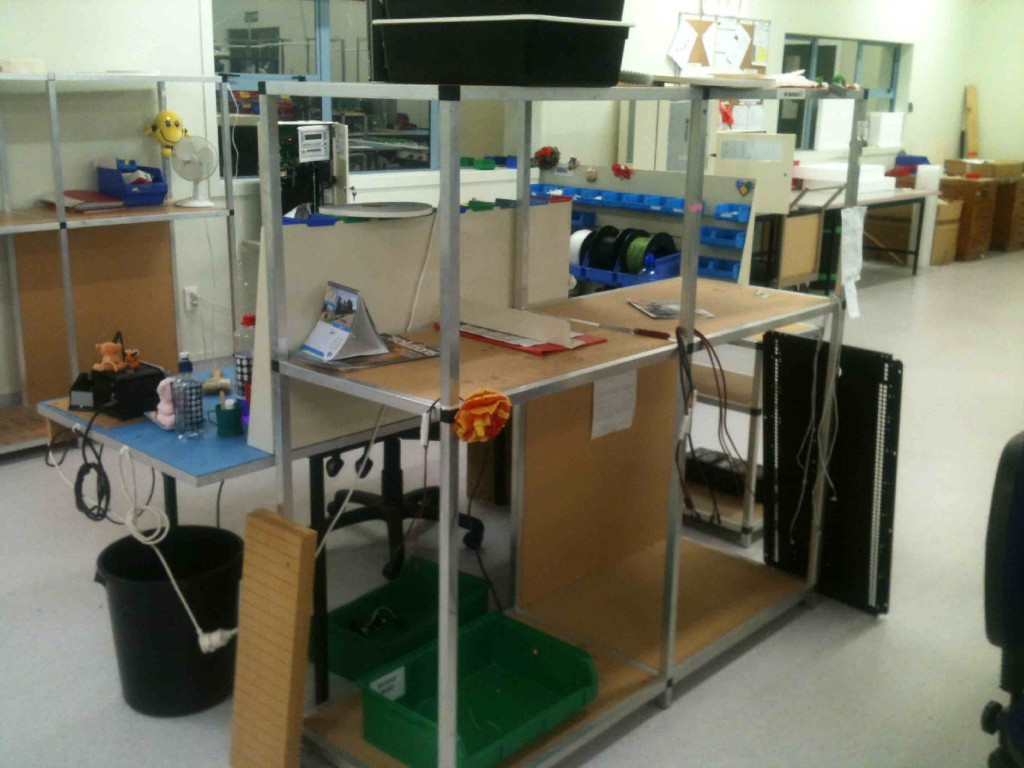

Close proximity cellular design reduces travel, increases communication & minimises work in progress.

Picture 1 (2012 ) shows two production lines located in close proximity to the end of the SMT production line (Pic 2 2015), reducing travel, improves communication and helps to limit WIP. Pic 3 illustrates continuous improvement activity with, shelving moved & replaced by inline meter mixing machine, connected to automated X/Y table.

To view each picture, click & hold on circle with arrows. Move left & right.

Before

Migrating to flow lines 2010.

Kanban & digital work instructions being phased in.

- Technician assembles product in its entirety, including prep work.

- Long lead times.

- Product not being tested as it is built increasing opportunity for large number of defects.

- Requires a test schedule.

- Increased work in progress.

- Increases opportunity for damage/obsolescence.

- Poorly utilised space.

After

Flow lines in operation 2015

- To left of picture is the In process Kanban with prepped components.

- Changeover time reduced from two days to 15~30 mins.

- TQM principles applied with each assembly technician checking the previous technicians work, aided by computer based schematic, BOM, digital pictures, videos and instuctions.

- Modular line design for mobility during relayout.

- Pneumatic tooling changed to electric, reducing noise and accomodating modular relayout.

- Secondhand wavesolder purchased & installed. Utilises spray fluxer instead of foam fluxer, improving solder joint quality and reduces cleaning.

- Old wavesolder provides spare parts in the event of breakdown

- Grey cupbards in background provide critical spare parts kanban. 5S ‘Shine’ cupboard holds cleaning supplies and tools for assembly technician team.

Before

Visual management not possible.

- Obstructive shelf design breaks down communication & creates silos.

- Shelves allow clutter to accumulate untidily.

- Pneumatic tooling restricts ease of relayout.

After

Flow line 2015

- Integrated, real time, in process testing finds defects immediately after unit build and provides immediate feedback loop for the rest of the product run.

- Prepping station in foreground re-designd with ergonomic bench, shadow board and castors for mobility.

Before

Test department

- Test department is to the left in the picture. Untidy and visual management not possible.

- Department was broken down and integrated into continuous flow lines.

After

U Shape Production Cell

- Accommodates good communication for frequent changeover.

- Accomodates 1.5 changeovers per day on average.

- Designed to facilitate low volume / high variety product range.

- Centralised inventory expediting SMED changeover.

Before

- 5S principles not applied. Untidy area wastes time as technicians must search and find items.

- Partially tested product in foreground. Technicians switching from product to product attempting to satisfy demand from final assembly.

After

Floor space now occupied by a production cell complete with…

- Digital work instructions.

- Task lighting.

- Kanban.

- Continuous flow line with modular design for easy relayout.

Before

Production floor 2009.

- Work station methodology used in conjunction with kitting.

- Visual management not possible.

- Inconsistent assembly times from technician to technician make attempt at accurate schedule futile.

- Poor ergonomics & low level lighting places strain on operators, in turn leading to defects.

- 5S not applied & undefined shelving leads to untidy, cluttered work area.

- Obstructed walkways lead to mishandling and rework.

After

Production Floor 2015

- Continuous flow line up & running since 2010.

- Task lighting and ceiling lighting added.

- Ergonomic benches, seating and lighting designed into work space.

- Air conditioning adjusted and controlled. Avoids individual heaters, reducing fire risk & lowers costs.

Before

Production floor 2011

- Work station methodology being transitioned in preparation for production cell. (Left of picture)

- Flow line 1 fully operational. (Right of picture)

After

Production Floor 2015

- Production cell to the left. Flow line to the right.

- Continuous improvement in action. to the right, extraction units added & safety cover preventing flying leads.

- Clearly defined thoughway with adequate spacing.

Before

- Island workstations.

- Undefined pathways for movement of people, parts & assembled product.

- Inadequate provision for raw material & workspace.

After

- Clearly defined pathway.

- U shaped cells running alongside windows, with a standard footprint & making use of natural light.

- Kanban inventory centralised, along with department supervisor for good communication & visual management.

- (Note: Picture taken very recently after relayout. Significant room for improvement: cables foreground to be tidies & secured. Excess raw material)

Before

- Raw material resting on floor

- Causes damage.

- Poses tripping hazard.

After

- Kitting trolleys being phased in.

- Allocates known location.

- Prevents damage.

- Prevents accidents.

- Increases technician value add time.

Before

- Insufficient workspace.

- Undefined tooling & component locations. Leads to waste, defects and potential accidents.

- Work area being used as a throughway.

After

- Larger footprint provides a sufficient space to work.

- Technician provided a computer allowing access to the following – Digitised Work Instructions. Standard Drawings. Department schedules. Email communication for customisation details.

- U shape maximises floor space and includes soak test area (left of photo).

- Travel to soak test area eliminated, saving time and prevents accidents.

- Work area cannot be used as a throughway.

- 5S principles yet to be fully applied – shadow board & defined component locations.

- Strategically designed for trialling a flow line assembly concept. See CAD video.

Before

- Island workstation. Walkways all around and often used as throughway.

- Partially completed product sitting on bench in danger of being knocked over either by assembly technician or passing foot traffic.

After

- Newly designed workstation confirgured in standard U shape footprint at cell level.

- On a larger scale, the final assembly area was designed in U shape format making use of the natural light from windows.

- Component inventory centralised as Kanban for fast, easy access.

- This establishes clearly defined walkways, very important when being used to transport bulky goods.

- Large items from stores can now be pre-kitted and delivered through these paths.

Before

- Shelving not fit for purpose wasting space & gathering clutter.

After

- Kitting trolleys being phased in

- Allocates a known, safe location for components.

- Prevents damage.

- Prevents accidents.

- Pre kitting prevents high value technician looking for components & keeps production flowing.